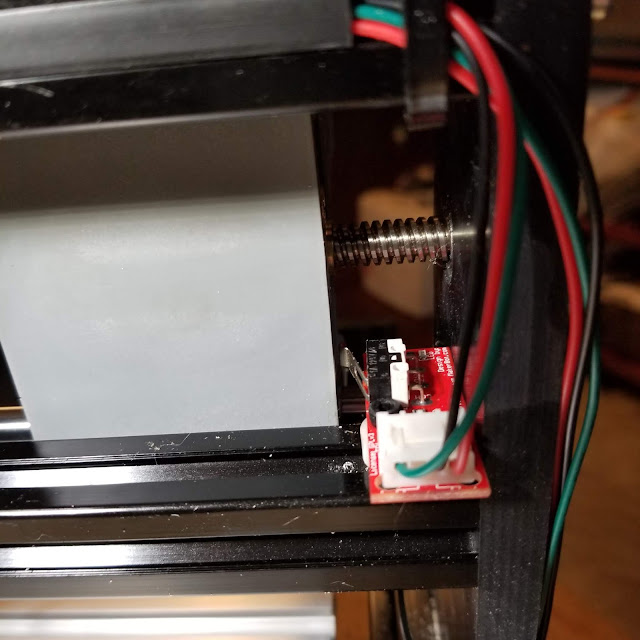

I added end stops to the CNC machine.

It now can find home position.

|

| Z end stop |

|

| x end stop |

|

| Y end stop. |

Tried to cut some 1/4 in baltic birch on the laser the other day.

It would not cut for squat.

I had seen others cutting the same material with their 5 watt lasers so I knew I was doing something wrong.

Turns out I was doing a LOT wrong.

I had the material way to far away from the laser,

I was trying to cut way too fast,

And I did not have any air assist.

Well, today I fixed those problems.

The air assist is very much jury rigged right now as I am waiting on tools and materials to do it right.

|

| Proper material hight found and air assist added. |

|

| It really does cut! |

I need to get a better spoil board of the proper height.

The 2x6 worked but it is far from flat.

The piece I cut out is a divider for the tray I am making for my cnc/laser toolbox.

When the parts and tools come in I will be making a better air assist but for now that works.

Y'all stay safe.

Thanks for giving such good knowledge. I got some helpful information from this post. Keep Posting such types of posts. CNC Glass Cutting Machine

ReplyDeleteI think this website contains some very good info for everyone : D. cnc machining

ReplyDeleteI have discovered that smart real estate agents all over the place are getting set to FSBO Advertising and marketing. They are acknowledging that it’s more than merely placing a sign post in the front area. It’s really regarding building relationships with these retailers who later will become consumers. So, when you give your time and energy to encouraging these retailers go it alone – the “Law associated with Reciprocity” kicks in. Good blog post. cnc milling manufacturer

ReplyDelete